Industry News

-

What are the common defects in injection molding of automobile bumper products?①

The application of automotive plastic parts has significant advantages in reducing vehicle quality, saving fuel, promoting environmental protection, and being recyclable. Most automotive plastic parts are injection molded. Tiger skin patterns, poor surface reproduction, sink marks, weld lines, wa...Read more -

Automotive Handle Mould

The gas-assisted process is a relatively complicated process. In general, the product is filled first, then the high-pressure inert gas is blown, the raw material in a semi-molten state is blown out, and the gas is used instead of the injection molding machine to obtain the product. Become a gas-...Read more -

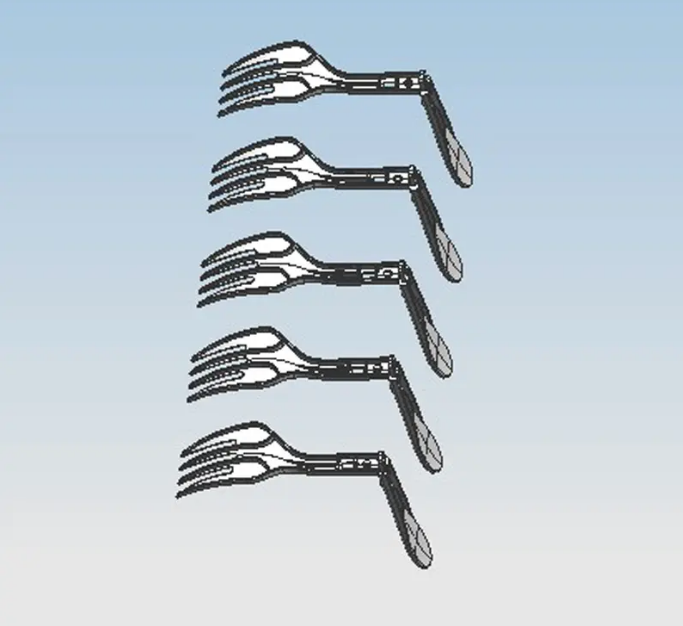

Plastic Fork Mould

It is important to know what steel and how many cavities needed. If have no clue, it is better to let us know injection machine parameters, then we can suggest maximum cavities based on the spoon/fork/spork dimension and weight. Plastic cutlery spoons require high yields to generate revenue. Ther...Read more -

Classification of plastic molds

According to the different methods of plastic parts molding and processing, it can be divided into the following categories: ·Injection mold Injection mold is also called injection mold. The molding process of this mold is characterized by placing the plastic raw material in the heating barrel of...Read more -

Overview and design of automotive molds

The most important part of the automobile mold is the cover mold. This type of mold is mainly a cold stamping mold. In a broad sense, “automotive mold” is the general term for molds that manufacture all parts on automobiles. For example, stamping molds, injection molds, forging molds,...Read more