It is important to know what steel and how many cavities needed. If have no clue, it is better to let us know injection machine parameters, then we can suggest maximum cavities based on the spoon/fork/spork dimension and weight. Plastic cutlery spoons require high yields to generate revenue. Therefore, the mould must ensure long life, short cycle, and product with light weight. We usually use H13, S136 stainless steel, these two materials are high hardness, can guarantee more than one million life.

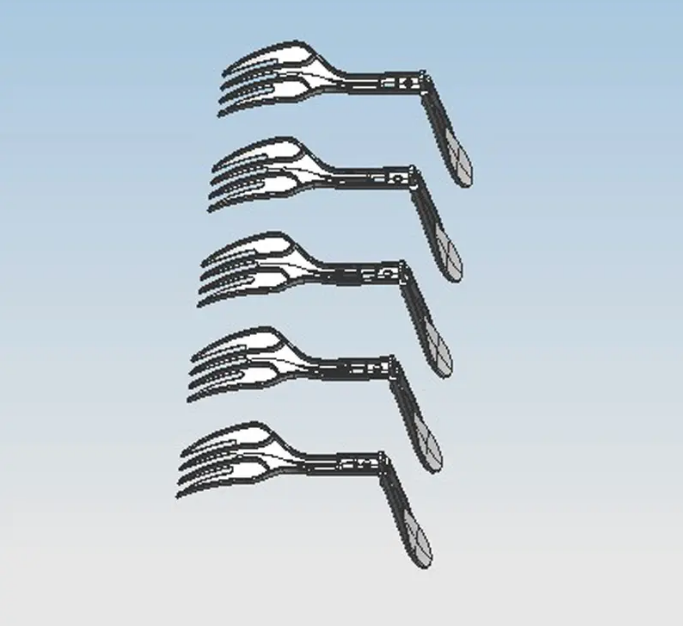

Another very important thing for foldable spoon mould making is the design. Product design should be reasonable, if some structural cannot be done by injection molding, it must be modified. Also a novel design will be popular in market. Combined with the parameters of the injection molding machine, we give an optimal solution for customers.

Usually we use 1-point hot runner, and some require more points. Of course, the cost is higher.

Next is the design of the cooling. This is related to the injection cycle. An excellent cooling system can guarantee short cycle and high output.

High quality moulds not only ensure the quality of injection molded products, but also to provide customers with an important basis for system solutions.

Sunwin has accumulated rich design experience and processing technology in folding cutlery moulds.

The plastic materials of cutlery and spoons generally include PP and PS. Depending on the plastic material, the choice of steel material for the mold is also different. The steel materials for cutlery and spoon molds are generally H13, S136, 2344, 2316, quenching materials and other steel materials. Because cutlery and spoon products are fast-moving consumer goods, the molds are generally open. It is multi-cavity and the mold shape is designed to be square or round. If the mold is designed to be square, a semi-hot runner can be used and the mold can be made into an insert type. The processing technology of Sino’s cutlery and spoon molds includes high-speed carving, high-speed milling, etc. Ordinary knife, fork and spoon molds are generally two-part molds, while folding knife, fork and spoon molds have additional sliders on the basis of the two-part mold. Therefore, folding cutlery and spoon molds are more difficult to make than ordinary cutlery and spoon molds.

Post time: Jan-10-2024