Products

-

Automotive Interior Parts Mould

Sunwin mold engineers have rich design experience and have a comprehensive development concept. The engineers adhere to the tenet of “the soul of the mold lies in the design”, and attach great importance to the mold making process. Carefully designed to provide the longest service life and fewer maintenance molds. Customers only need to provide 2D or 3D renderings or samples in DXF, DWG, PRT, SAT, IGES, STEP and other formats. Sunwin mold will scan the samples and make product blueprints. Once confirmed by the customer, it can be carried out according to the customer’s existing projects. Mould assembly, drawing design.

The company attaches great importance to technological innovation, and cooperates with a number of colleges and universities in industry, academia and research to give full play to their respective advantages and develop a powerful advanced system integrating research, development and production, and continuously improve the ability of independent innovation. Provide high-quality molds for world-renowned brand auto parts suppliers.

-

Gas Assisted Mould

Automotive center storage box mould design show Sunwin mold has over 20 years of rich experience in gas-assisted mold manufacturing, which can satisfy the mold making and injection of common gas-assisted products in the market, always serve the customer with high standard, high quality, fast delivery time, and competitive price. Gas-assisted injection cycle table The gas-assisted process is a relatively complicated process. In general, the product is filled first, then the high-pressure i... -

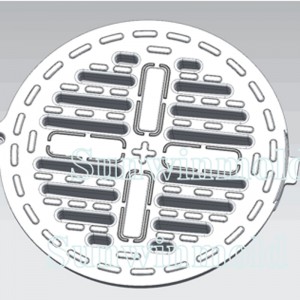

Sunwin Mold Company Spool Mould

spool mould show spool mold show spool mold show spool mold show spool mould show Textile spool mould, we adopt the most advanced warm runner design, it help to improvespeed of production into 5 shot times each minute, mould life to 3 million times. Mould shipment and service after sales 1. We will send engineer to install and adjust the mould till produce smoothly. 2. In the actual production process, because of the quality problem of the mold itself, I’ll send engineers ... -

Automotive Handle Mould

Sunwin mold has over 20 years of rich experience in gas-assisted mold manufacturing, which can satisfy the mold making and injection of common gas-assisted products in the market, always serve the customer with high standard, high quality, fast delivery time, and competitive price.

-

Automotive Exterior Trim Parts Mould

Sunwin mold engineers have rich design experience and have a comprehensive development concept. The engineers adhere to the tenet of “the soul of the mold lies in the design”, and attach great importance to the mold making process. Carefully designed to provide the longest service life and fewer maintenance molds. Customers only need to provide 2D or 3D renderings or samples in DXF, DWG, PRT, SAT, IGES, STEP and other formats. Sunwin mold will scan the samples and make product blueprints. Once confirmed by the customer, it can be carried out according to the customer’s existing projects. Mould assembly, drawing design.

The company attaches great importance to technological innovation, and cooperates with a number of colleges and universities in industry, academia and research to give full play to their respective advantages and develop a powerful advanced system integrating research, development and production, and continuously improve the ability of independent innovation. Provide high-quality molds for world-renowned brand auto parts suppliers.

-

Automotive Front Door Panel Mould

Sunwin mould has been producing many kinds of automotive mold, auto front door and rear auto door; auto door with speaker mesh and auto door w/o speaker mesh. Sunwinmould has consider the following issues during auto door mould designing and manufacturing: to avoid many injection defect of auto door, Any sharp, shrink mark, melting line, scratch and under filled

1. Reasonable size of mould base.

2. Design the reasonable parting line, it will be convenient for auto door mould assembly and manufacturing.

3. Injection gate needed more than 3 drops for the auto door mold. The melt line will appear at the two point meeting area.

4. Ensure the ejecting system be safe and reasonable. Since many lifter and ejector for auto door mould, avoid the sharp caused by the small error during auto door mould manufacturing.

5. Water line must be applied as much as possible, and the dia. of water line should be large as much as possible.

6. Avoid air exhaust when the auto door mould with speaker mesh.

-

Plastic Test Tube Mould

Plastic test tube mould, plastic blood test tube mould, plastic blood collect tube mould, PET test tube mould conical centrifugetube mould, centrifuge tube mould, test tube rack mould, Plastic test tubes are usually made of PE, PP and PS. Disposable plastic test tubes are divided into ordinary test tubes, test tubes with tubes, centrifugal tubes, etc.

Three kinds of common test tubes are commonly used in the laboratory. They are used as reaction containers for a small amount of reagents at room temperature or when heated. A test tube with a tube is installed on the basis of a common test tube, which can be used for gas washing, and can also be used to assemble a very simple Keppel generator. The centrifuge tube is a common tubular container in the laboratory, with an empty cap and a gland. The function of the centrifuge tube cap is to prevent liquid leakage and sample volatilization, Support centrifugal pipe to prevent deformation of centrifugal pipe.

-

Automotive Back Bumper Mold

Sunwin mold has been supplying the front auto bumper mould, back auto bumper mould and auto grille mould to well-known automobile manufacturers at home and abroad. With the improving of customer’s request for surface of car bumper mold, the old mould design structure method can’t meet the need of market. Sunwinmold have been always accumulating the experience and Improve and optimize the mould design of auto bumper mould.

1. Structure of hidden parting line for automotive bumper mould: Sunwinmold can master the structure and set the parting line on the non exterior surface to be ejected, so it will avoid small step on the surface of auto bumper and easy to cut flashes. Then it helps to realize the smooth surface of auto bumper.

2. The location of injection gate: We will make moldflow analyse, The reasonable location of injection gate could reduce the pressure difference of cavity, it directly affects the quality of auto bumper.

3. The location of taking injection part: Leave the injection part on cavity side or core side We have to consider the reasonable structure of auto bumper mould ejection system.

-

Automotive Front Bumper Mold

Sunwin mold has been supplying the front auto bumper mould, back auto bumper mould and auto grille mould to well-known automobile manufactures at home and abroad. With the improving of customer’s request for surface of car bumper mold, the old mould design structure method can’t meet the need of market. Sunwinmold have been always accumulating the experience and Improve and optimize the mould design of auto bumper mould.

1. Structure of hidden parting line for automotive bumper mould: Sunwinmold can master the structure and set the parting line on the non exterior surface to be ejected, so it will avoid small step on the surface of auto bumper and easy to cut flashes. Then it helps to realize the smooth surface of auto bumper.

2. The location of injection gate: We will make moldflow analyse, The reasonable location of injection gate could reduce the pressure difference of cavity, it directly affects the quality of auto bumper.

3. The location of taking injection part: Leave the injection part on cavity side or core side We have to consider the reasonable structure of auto bumper mould ejection system.

-

12 Cavity Wide Mouth PET Preform Mould

12 cavity wide mouth preform mold

The wide-mouth preform mold is also called the jar preform mold. Wide mouth preforms are mainly designed for candy or nut packaging. We are many years behind the wheel in this field. We provide needle valve hot runner system and short gate hot runner system for different wide mouth preforms.

-

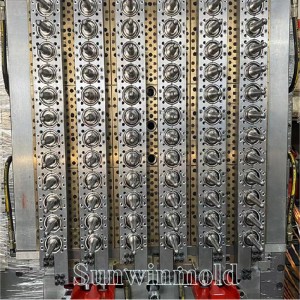

72 Cavity PET Preform Mould

72-cavity PET preform mold manufacturing

72-cavity PET preform mold

-

Composite Mould

Sunwin Mould is a professional composite molds manufacturer, we produce various glass fiber composite molds, SMC, BMC, GMT, LFT-D, HP-RTM, CFRP, RTM mould carbon fiber composite molds.