Tiger skin pattern

Tiger skin pattern often appears on larger automotive injection molded parts such as bumpers, instrument panels, door panels and pillars. It is a surface defect with wavy stripes, approximately perpendicular to the direction of melt flow, forming a luster on the surface of the part. Different engravings look like patterns on tiger skin, commonly known as tiger skin patterns.

1. Where do tiger skin lines usually appear?

Tiger skin pattern is easy to occur on parts with thin wall thickness and large process. It has the following characteristics: (1) Periodically changing light and dark stripes appear on the surface of the injection molded part; (2) The stripes are roughly perpendicular to the melt. The flow direction; (3) The stripes are divided into bright areas and dark areas. The bright areas have high gloss and the dark areas have poor gloss; (4) If the front of the part is a bright area, the back is a dark area. Both appear alternately.

2. Why do tiger skin lines appear easily?

The more toughening systems in the material, the easier it is for the tiger skin phenomenon to occur.” Materials with poor toughness rarely have tiger skin phenomena, such as reinforced materials, non-toughened nylon, PBT and other materials during the molding process. Tiger skin texture occurs. PP materials used in automotive injection molded parts require high impact properties and are added with toughening ingredients such as EPDM and POE, so tiger skin texture defects are very likely to occur.

3. How to improve tiger skin lines?

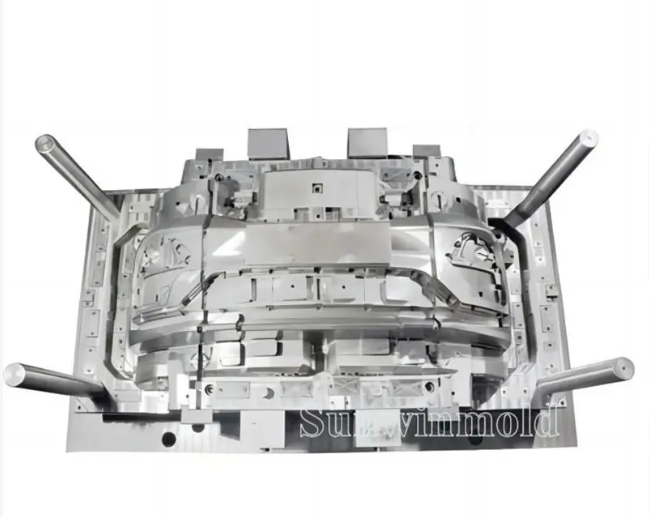

1) In terms of mold design, increasing the diameter of the flow channel and expanding the thickness and width of the gate are effective measures to eliminate tiger skin lines. The gate thickness should preferably be 0.7 to 0.8 times the wall thickness. The purpose of this is to reduce the pressure loss of the melt in the runner and gate, and reduce the ejection expansion effect when entering the mold cavity.

2) In the injection molding process, increasing the melt temperature and mold temperature and adjusting the injection speed will help eliminate tiger skin lines. In general, using a lower firing rate is beneficial to eliminating tiger skin lines because the melt flow is more stable at low speeds.

Post time: Jan-16-2024