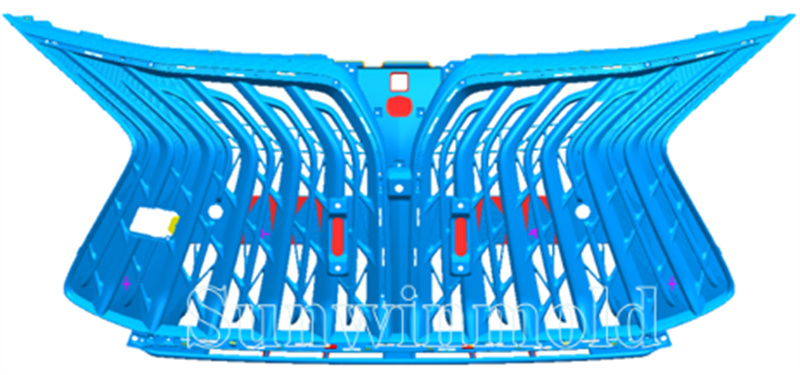

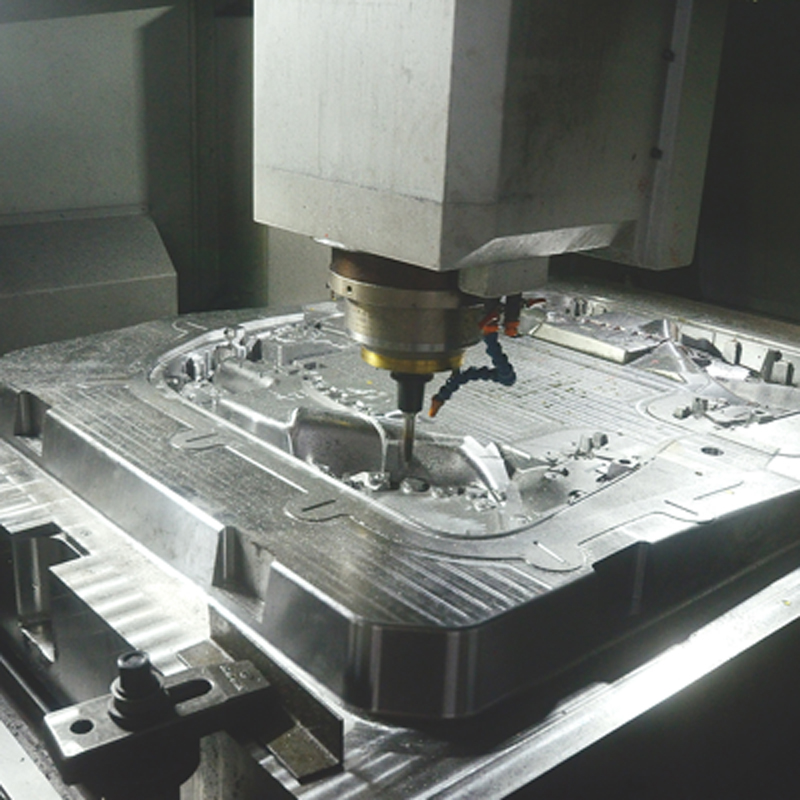

Automotive Grille Mould

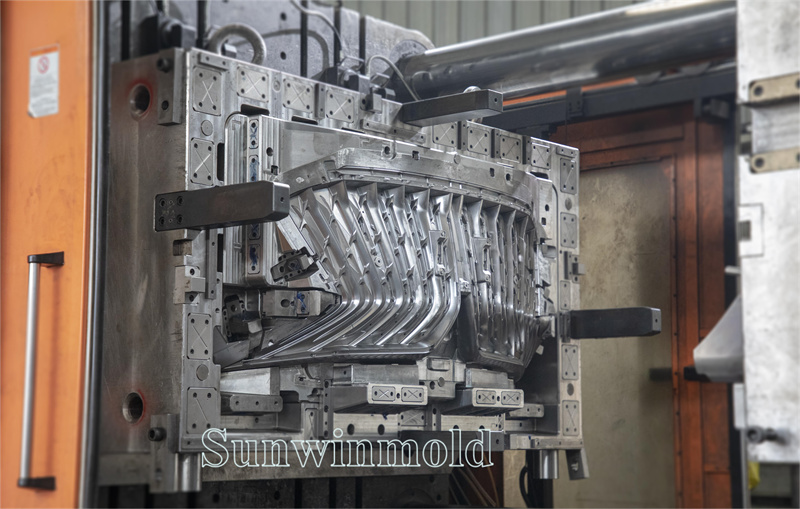

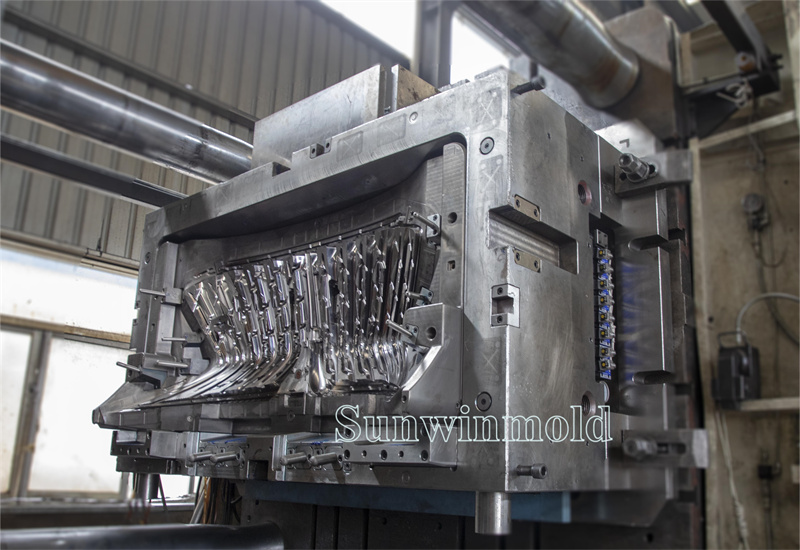

Automotive grille mould show

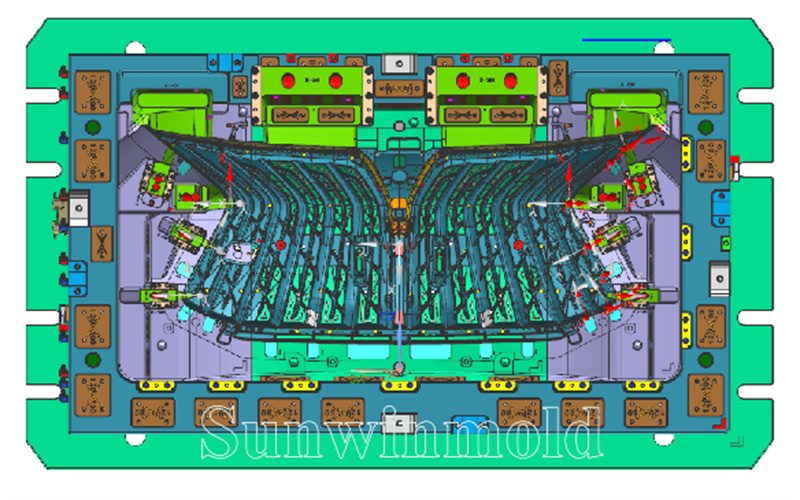

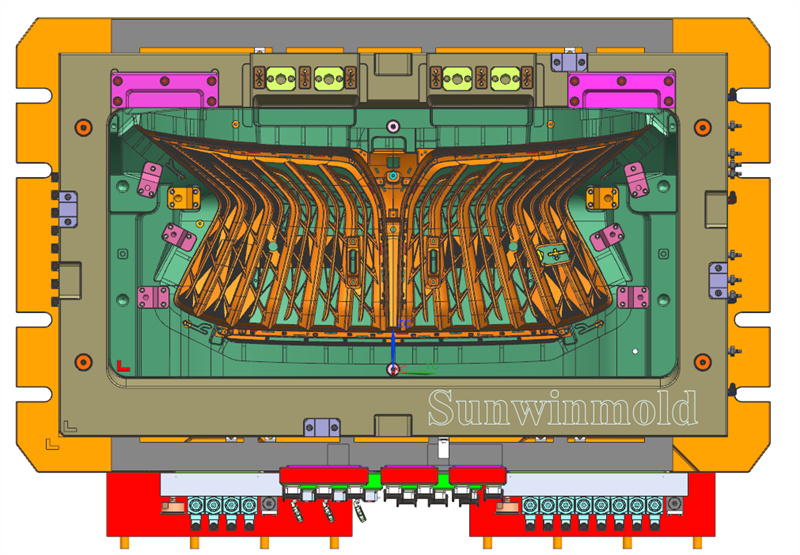

Sunwinmould produced a specular injection mould adopting an electrical heating way, mainly aiming at solving the problems that after an existing multi-sprue injection mould is used, weld marks are easily generated in the surface of a product, and the like. The specular injection mould adopting the electrical heating way comprises a front mould arranged on a fixed mould plate of an injection molding machine, a rear mould arranged on a movable mould plate of the injection molding machine, a heating mold core, and a cooling plate used for cooling injection molded products; an electrical heating element is buried in the heating mold core. According to the specular injection mould adopting the electrical heating way, heating and cooling are independently and separately carried out, so that the heat transfer efficiency of the mould is high, and the production efficiency of the specular injection mould is further improved; furthermore, a water way in the cooling plate only takes part in cooling, so that an integrated part does not need to be designed, and the structure of the mould is greatly simplified.

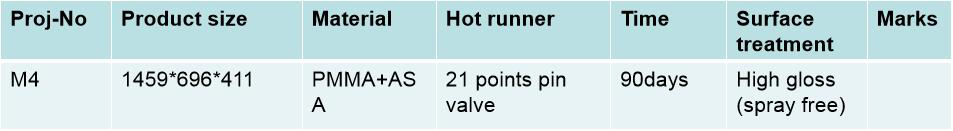

High light injection molding main parameters

Project: Main parameter description

Mold temperature: When the mold is injection molded, the temperature is about 80 °C-130 °C, and the mold temperature is reduced to 60-70 °C when the pressure is maintained. The cavity surface is mirror polished. Water vapor heating, 3 point needle valve into the glue.

Mold steel: 1. CPM40/GEST80 (Greitz, Germany) 2. CENA1 (Datong, Japan) 3. MIRRAX40 (Swedish one wins 100).

Mold cooling water: The water channel adopts a hole diameter of 5-10mm, the spacing is about 35mm, and the surface of the product is 8-12mm. The electric thermocouple is designed to accurately control the temperature, and the high temperature water pipe is designed on the non-operation side.

Mold insulation: The dynamic mold inserts need to be hollowed out to design the heat insulation board, the mold frame design water path, the guide column design side guide column, the mold exhaust 10mm section, the mold parting surface sealing surface design 10mm.

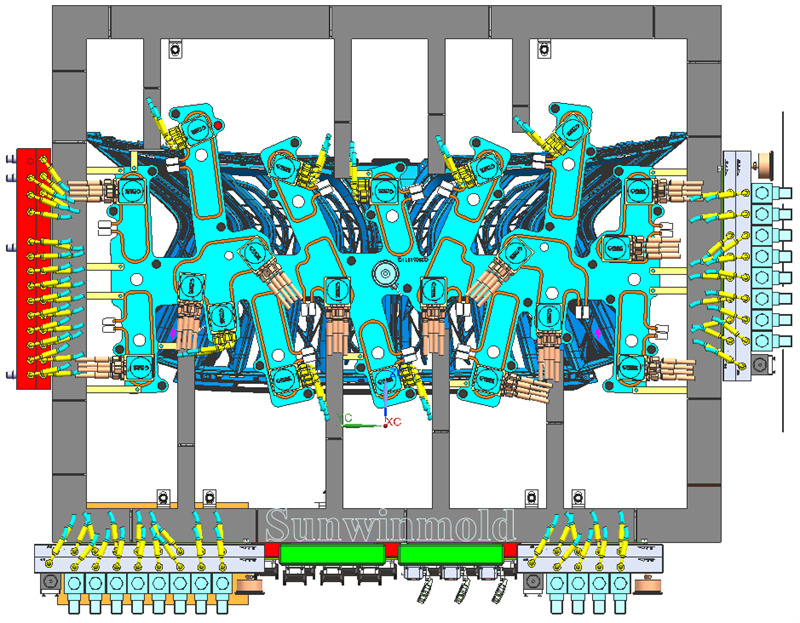

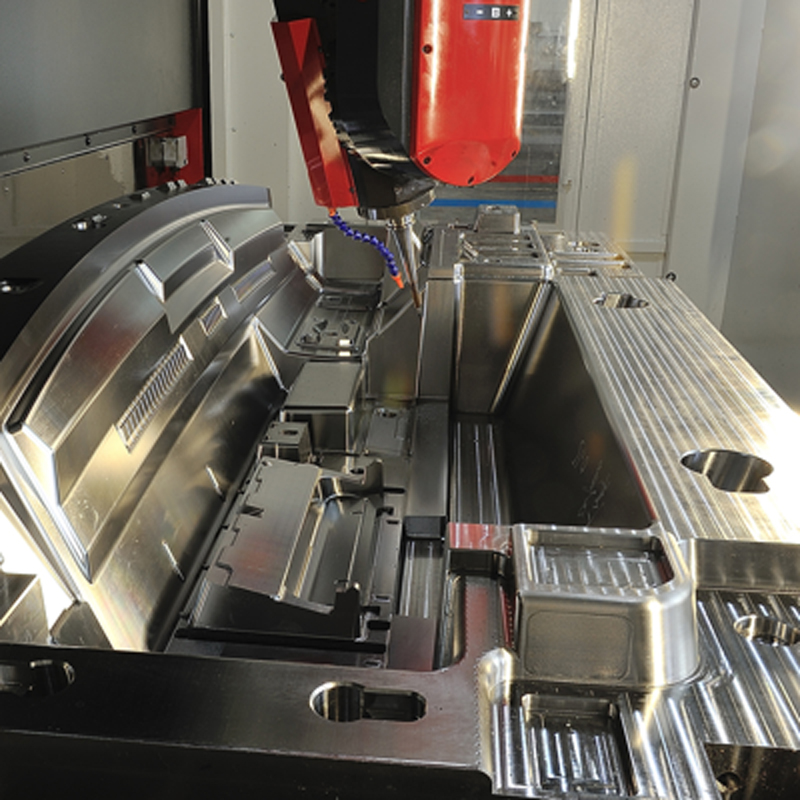

Automotive grille mould design show

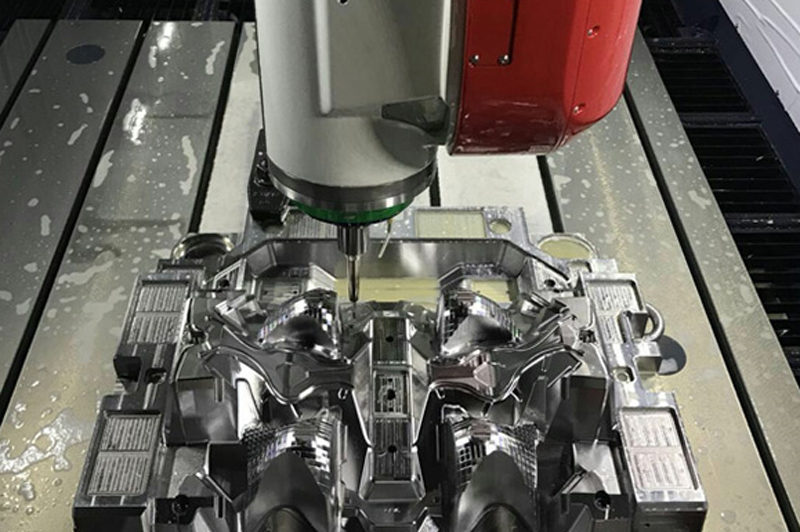

Equipment

Mould shipping to customer

FAQ

Q: Do you make molds for many automtive parts?

A: Yes, we make molds for many auto parts, such as front auto bumper mould, back auto bumper mould and auto grill mould , etc

Q: Do you have injection molding machines to produce parts?

A: Yes, we have our own injection workshop, so we can produce and assemble according to customer requirements.

Question: What kind of mold do you make?

A: We mainly manufacture injection molds, but we can also manufacture compression molds (for UF or SMC materials) and die casting molds.

Q: How long does it take to make a mold?

A: Depending on the product size and the complexity of the parts, it is slightly different. Generally speaking, a medium-sized mold can complete T1 within 25-30 days.

Q: Can we know the mold schedule without visiting your factory?

A: According to the contract, we will send you the mold production plan. During the production process, we will update you with weekly reports and related pictures. Therefore, you can clearly understand the mold schedule.

Q: How do you guarantee the quality?

A: We will appoint a project manager to track your molds, and he will be responsible for each process. In addition, we have QC for each process, and we will also have a CMM and online inspection system to ensure that all components are within tolerance.

Q: Do you support OEM?

A: Yes, we can produce through technical drawings or samples.